| Chrome Qws Rod Npe | |

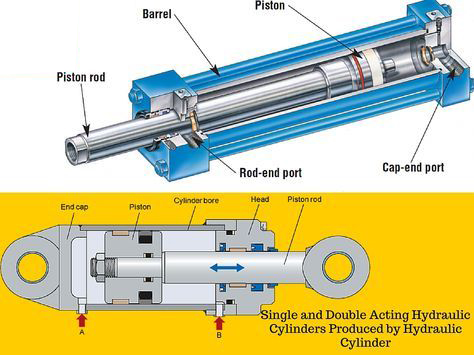

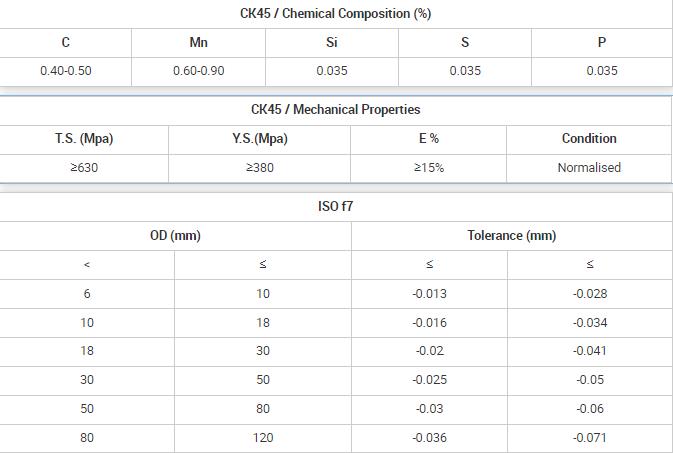

| Chrome-plated HYDRAULIC pas, nto chrome thickness 20u-25u, od thev ISOF7, Roughness Ra0.2, Ncaj Nraim 0.2 / 1000, Khoom CK45 | |

| OD | qho hnyav |

| (hli) | M / kg |

| 4 | 0.1 |

| 6 | 0.2 |

| 8 | 0.4 |

| 10 | 0.6 |

| 12 | 0.9 |

| 14 | 1.2 |

| 15 | 1.4 |

| 16 | 1.6 |

| 18 | 2.0 |

| 19 | 2.2 |

| 19.05 | 2.2 |

| 20 | 2.5 |

| 22 | 3.0 |

| 25 | 3.9 |

| 28 | 4.8 |

| 30 | 5.5 |

| 32 | 6.3 |

| 35 | 7.6 |

| 38.1 | 8.9 |

| 40 | 9.9 |

| 44.45 | 12.2 |

| 45 | 12.5 |

| 50 | 15.4 |

| 50.8 | 15.9 |

| 55 | 18.6 |

| 56 | 19.3 |

| 57.15 | 20.1 |

| 60 | 22.2 |

| 63 | 24.5 |

| 63.5 | 24.9 |

| 65 | 26.0 |

| 69.85 | - |

| 70 | 30.2 |

| 75 | 34.7 |

| 76.2 | 35.8 |

| 85 | 44.5 |

| 88.9 | 48.7 |

| 90 | 49.9 |

| 95 | 55.6 |

| 100 | 61.7 |

| 101.6 | 63.6 |

| 105 | 68.0 |

| 110 | 74.6 |

| 115 | 81.5 |

| 120 | 88.8 |

| 127 | 99.4 |

| 140 | 120.8 |

| 145 | 129.6 |

| 150 | 138.7 |

| 152.4 | 143.2 |

| 170 | 16.2 |

| 180 | 199.7 |

Sau koj cov lus ntawm no thiab xa mus rau peb